Recently, dozens of provinces and cities, including Jiangsu, Zhejiang, Shandong, Henan, Sichuan, Guangdong, Ningxia, Guiyang, Dalian, Heilongjiang and Shaanxi, have issued notices, specific plans or drafts for soliciting opinions on the investigation and rectification of hazardous wastes.

Among them, chemical enterprises involving hazardous wastes and waste hazardous chemicals have become the focus of investigation in many places.

Some people in the industry said that it is expected that the supervision of hazardous waste storage, transportation and disposal will become more and more stringent in the future, or reduce the amount of hazardous waste of non-standard disposal in chemical plants, and the real demand for hazardous waste disposal will appear.

At the same time, under strict supervision, disposal standards will be raised, small factories with irregular operation of hazardous waste disposal will be closed, and industrial concentration will be enhanced under the survival of the fittest.

In 2019, the Ministry of Ecology and Environment will continue to deploy and carry out the "waste removal Action 2019" and achieve full coverage of 126 cities in the Yangtze River Economic Belt, and further urge local party committees and governments to implement the main responsibility of solid waste supervision. severely crack down on illegal transfer, dumping, disposal of solid waste and other illegal activities, so as to promote provinces and cities along the river to truly grasp large-scale protection and refrain from large-scale development.

In order to help enterprises better cope with the requirements of the new situation of environmental protection and improve the standardized construction and operation level of hazardous waste disposal facilities, we will share with you the relevant matters needing attention on hazardous waste inspection.

Contents of on-site inspection and key points of specification

1.Hazardous waste storage facility

Check the content:

1.

Whether the measures such as "windproof, rainproof, sunscreen, anti-seepage and anti-corrosion" in the warehouse are perfect; whether to build a leak-proof collection device.

two。.

Whether there is a cofferdam in the hazardous waste warehouse to prevent the liquid in the warehouse from flowing out of the warehouse and to prevent Rain Water from pouring into the warehouse at the same time.

3.

Whether there are gas guide outlets, gas purification devices, safety lighting facilities, observation windows, etc., in the warehouse.

example:

Key points of standardization:

1.

Hazardous waste storage facilities shall be built outside the warehouse of flammable, explosive and other dangerous goods and the protective area of high-voltage transmission lines.

two。.

The floor of the storage site shall be hardened and coated with at least epoxy resin with high 2mm density to prevent leakage and corrosion.

3.

There must be leaking liquid collection devices (collection ditches and collection wells to collect leachate and prevent leakage), gas outlets and gas purification devices.

There should be safety lighting and observation windows in the facility.

4.

The place used to store liquid and semi-solid hazardous waste containers must have a corrosion-resistant hardened ground with no cracks on the surface.

5.

The skirt foot shall be designed to intercept the leaking skirt, and the volume of the ground and the skirt shall not be less than 1/5 of the maximum or total reserves of the largest container.

6.

Incompatible hazardous wastes must be stored separately and partitioned.

Check the content:

1.

Whether the container containing hazardous waste is intact.

two。.

Whether the containers and packages containing hazardous waste are all labeled with hazardous waste.

Example:

Key points of standardization:

1.

Containers containing hazardous waste must be in good condition.

two。.

The materials and linings of containers containing hazardous waste should be compatible with hazardous waste (do not react with each other).

3.

Enough space should be left in the container containing liquid and semi-solid hazardous waste, and the space above 100mm should be reserved between the top of the container and the surface of the liquid.

4.

Containers containing hazardous waste must be affixed with the label shown in Appendix An of the Hazardous waste Storage pollution Control Standard.

3.Contents of hazardous waste stacking inspection:

1.

Whether it is collected and stored according to the characteristics of hazardous waste.

two。.

Whether the stacking height and wall distance are in accordance with the specification.

example:

Key points of standardization:

1. The foundation must be impervious, and the impervious layer shall be at least 1 meter thick clay layer (permeability coefficient ≤ 10-7 cm / s), or 2 mm thick high density polyethylene, or at least 2 mm thick other artificial material, permeability coefficient ≤ 10-10 cm / s.

two。.

Enterprises must collect and store them according to the characteristics of hazardous wastes, and incompatible hazardous wastes cannot be stacked together.

3. The lining is placed on a foundation or base; the lining should be able to cover the areas that may be involved in hazardous waste or its leachate; the lining material is compatible with the stacking of hazardous waste; and a leachate collection and removal system is designed and constructed on the lining.

4. Hazardous waste piles should be protected against wind, rain and sun.

5. Similar hazardous wastes contained in containers can be stacked and stored; there should be a handling channel between each stack.

4.Contents of storage management inspection:

1. Whether there is a hazardous waste account, and combined with the hazardous waste account to check whether the type, quantity and disposal of hazardous waste produced by the enterprise are consistent with the EIA.

2. Hazardous waste transfer list (whether the hazardous waste transfer plan has been examined and approved, whether the enterprise truthfully fill in the column of the generating unit in the transfer form and affix its official seal).

3. Whether to establish and improve the hazardous waste pollution prevention and control system, whether the person in charge is clear, the responsibility is clear, and whether the person in charge is familiar with the relevant laws, regulations, standards and norms of hazardous waste management.

4. Whether hazardous wastes are transferred in time.

5. The lock condition of the hazardous waste warehouse.

example:

Key points of standardization:

1. Both the producer of hazardous waste and the operator of hazardous waste storage facility shall keep a record of the situation of hazardous waste, the name, source, quantity and characteristics of hazardous waste, the type of packaging container, the date of storage, the location of storage, the date of discharge of the waste and the name of the receiving unit shall be marked on the record.

Hazardous waste records and manifests shall be retained for three years after hazardous waste is recovered.

2. Hazardous waste storage rooms shall be managed in accordance with the "double-person double-lock" system.

(the two keys shall be managed by two persons in charge of hazardous waste respectively, not by one person).

3. The storage of hazardous waste shall not exceed one year, and shall be submitted to the environmental protection department for examination and approval.

5.Safety protection of storage facilities

Check the content:

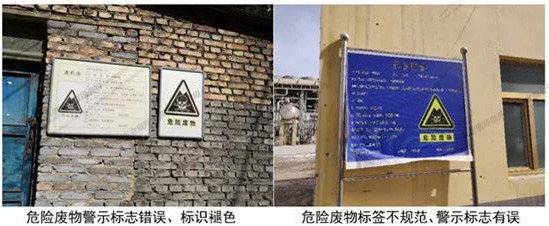

1. Whether the hazardous waste storage site has set up hazardous waste warning signs and hazardous waste labels, and whether the signs are correct, clear and intact.

2. Whether hazardous waste storage sites are equipped with emergency protection facilities, fire protection facilities, etc.

example:

Key points of standardization:

1. Facilities and places for storing hazardous waste shall at the same time set up hazardous waste warning signs and hazardous waste labels and post them on or on both sides of the doors of hazardous waste warehouses.

2. Walls or other protective fences shall be set up around hazardous waste storage facilities.

3. Hazardous waste storage facilities shall be equipped with communication equipment, lighting facilities, safety protective clothing and tools, and emergency protective facilities.

Common hidden trouble:

1.Hazardous waste warehouse is not standard;

2.Non-standard labeling of hazardous waste;

3.The transfer of hazardous waste is not in time.;

4.Self-built hazardous waste treatment equipment and facilities are not in operation;

5.Some enterprises do not have clear and detailed accounts for hazardous waste.;

6.Failure to effectively classify hazardous waste;

7.Unable to complete the declaration of information related to dynamic management of hazardous waste and implement the joint order system on time.

Website of this article:http://www./news_view_32_107.html